Fry breeding intelligent production system

| Fry breeding intelligent production system | |||||||

| _________________________________________________________________________________________________________ | |||||||

|

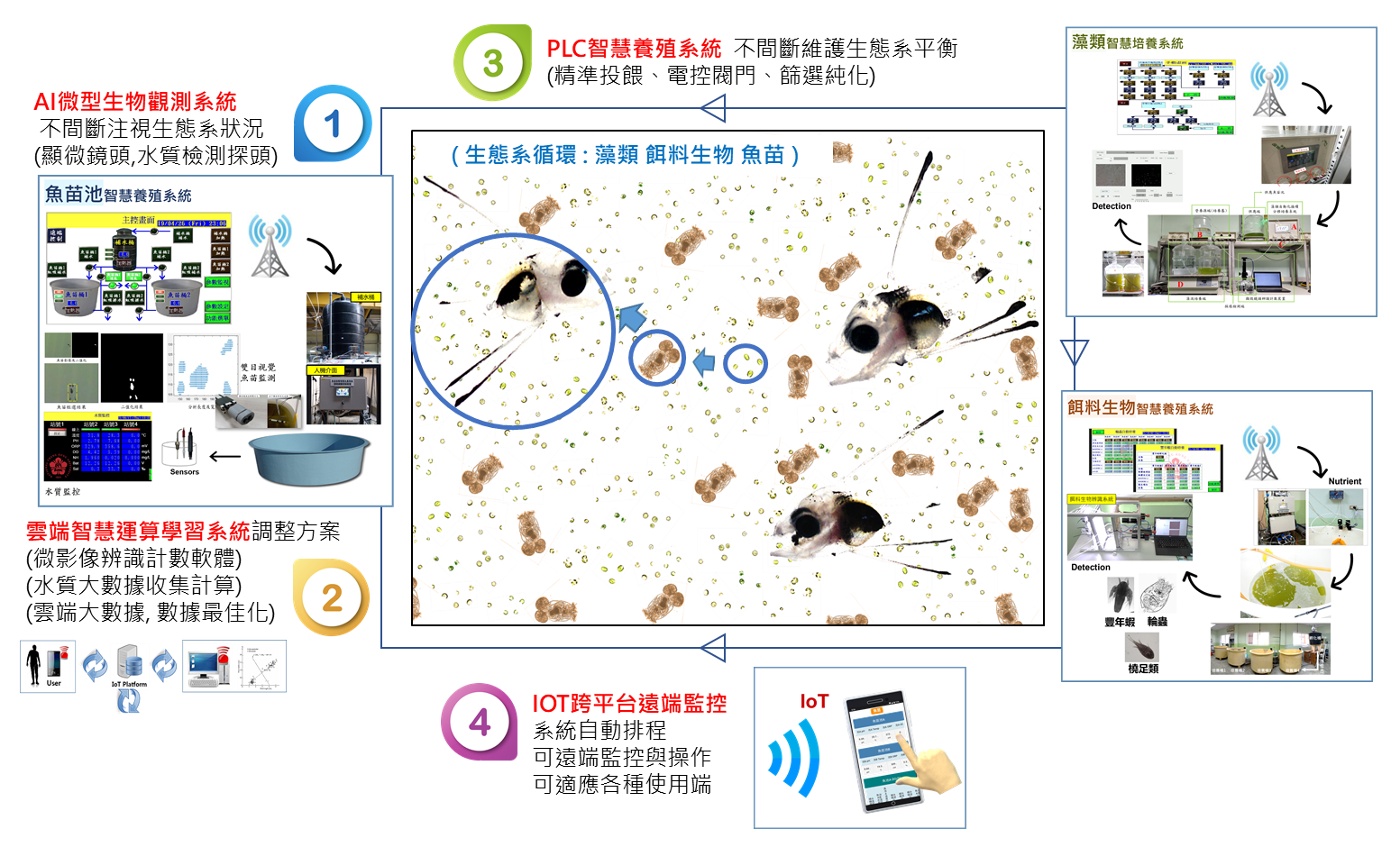

Global marine fisheries are gradually depleting, and aquaculture fisheries are rising. At present, global aquaculture production is increasing at an annual rate of 8%, and 90% of them are concentrated in Asia (FAO, 2016). The aquaculture industry in Taiwan is also one of the important basic agriculture, but its production has been stagnating at 300,000 tons many years (F.A., 2020) and there has been no breakthrough in the development of fry breeding technology. The main reason is that the aquaculture industry in Taiwan is mostly extensive and small-scale. The related breeding procedures and environmental management information are difficult to inherit, which is not conducive to product management and resume tracking and makes improvement and progress extremely difficult. Therefore, guiding aquatic technology toward automation, intelligence, and leading inheritance are the main tasks of the intelligent fry production system. The core of the system takes modularization, standardization and multi-function as the main concepts. It uses programmable logic controller for decision-making and connection of the intelligent breeding system. It connects various valves, sensors, controllers, computers and other systems through various interfaces, which have the advantages of low failure rate and high reliability, and combines with peripheral equipment such as artificial intelligence, Internet of Things, machine learning and other technologies. It can fast and simply add or replace various modules without costly modifications to the system and keep pace with the modern technology.

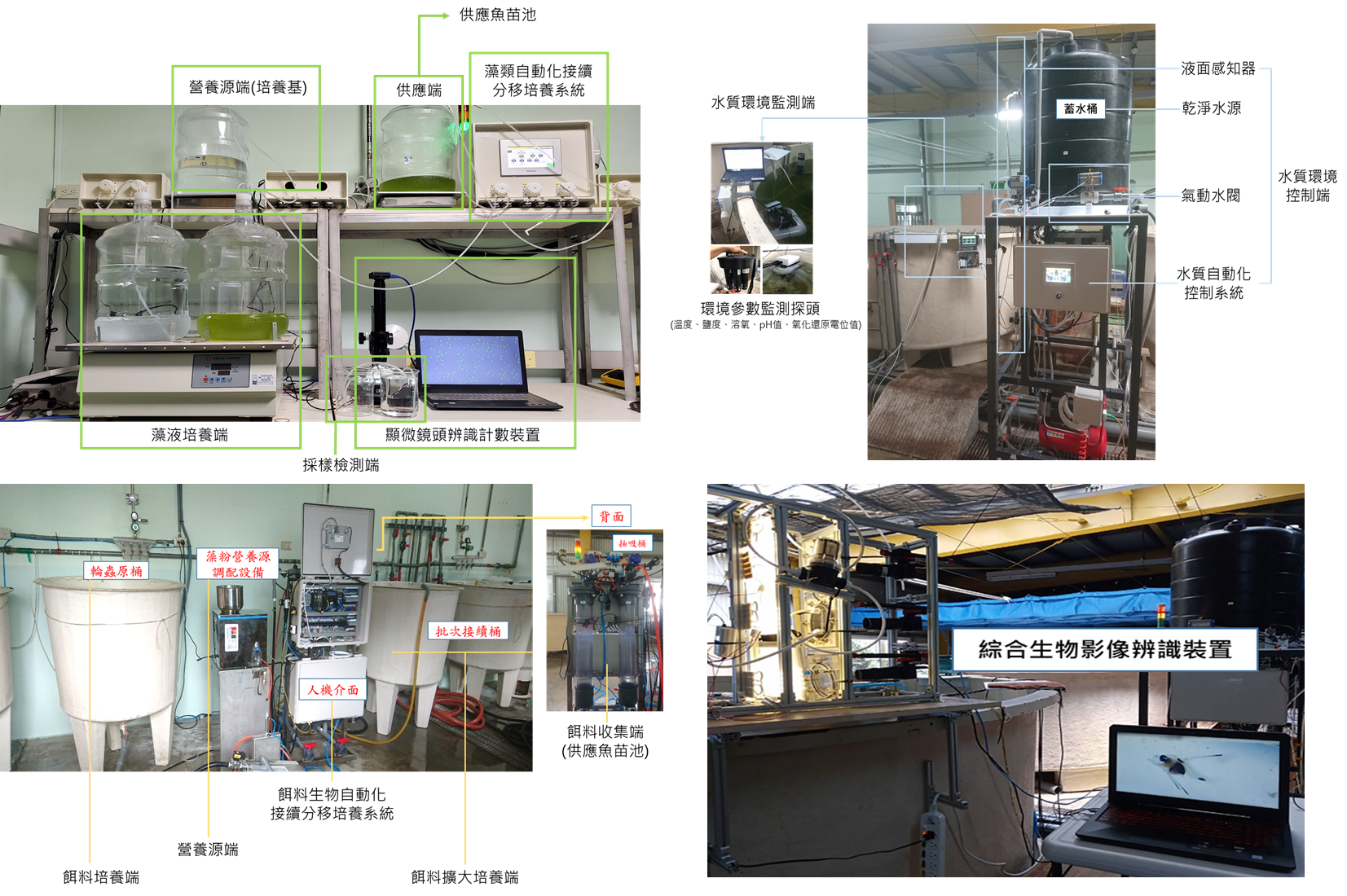

The peripheral systems contain the micro-organism observation system that is used to observe the length and width of the fry through stereo vision, the plate-type biometric device which can provide accurate biological data and make decision for culturing of live-food organisms, and quantitative suction device to provide accurate feeding. The control of the system can be carried out at the remote end and cross-platform to achieve a completely unmanned design. Compared with traditional artificial breeding, the current experimental results of fry harvest have reached 3.85 times and 2.38 times in giant grouper and orange-spotted grouper and achieve a stable breeding condition.

By breeding in the intelligent way with various modules, the intelligent fry production system can reduce the manpower requirement and achieve the goal of saving costs and stabilizing the output. It is expected to save 60% labor, 40% production cost, improve fry growth rate through big data compared with traditional farming, and form a complete intelligent production chain with the adult fish intelligent breeding system. It is helpful for the overall output value of aquaculture industry in Taiwan and the policy promotion of Smart Farming.

|

|||||||

|

Fig. 1 The concept of Fry breeding intelligent production system

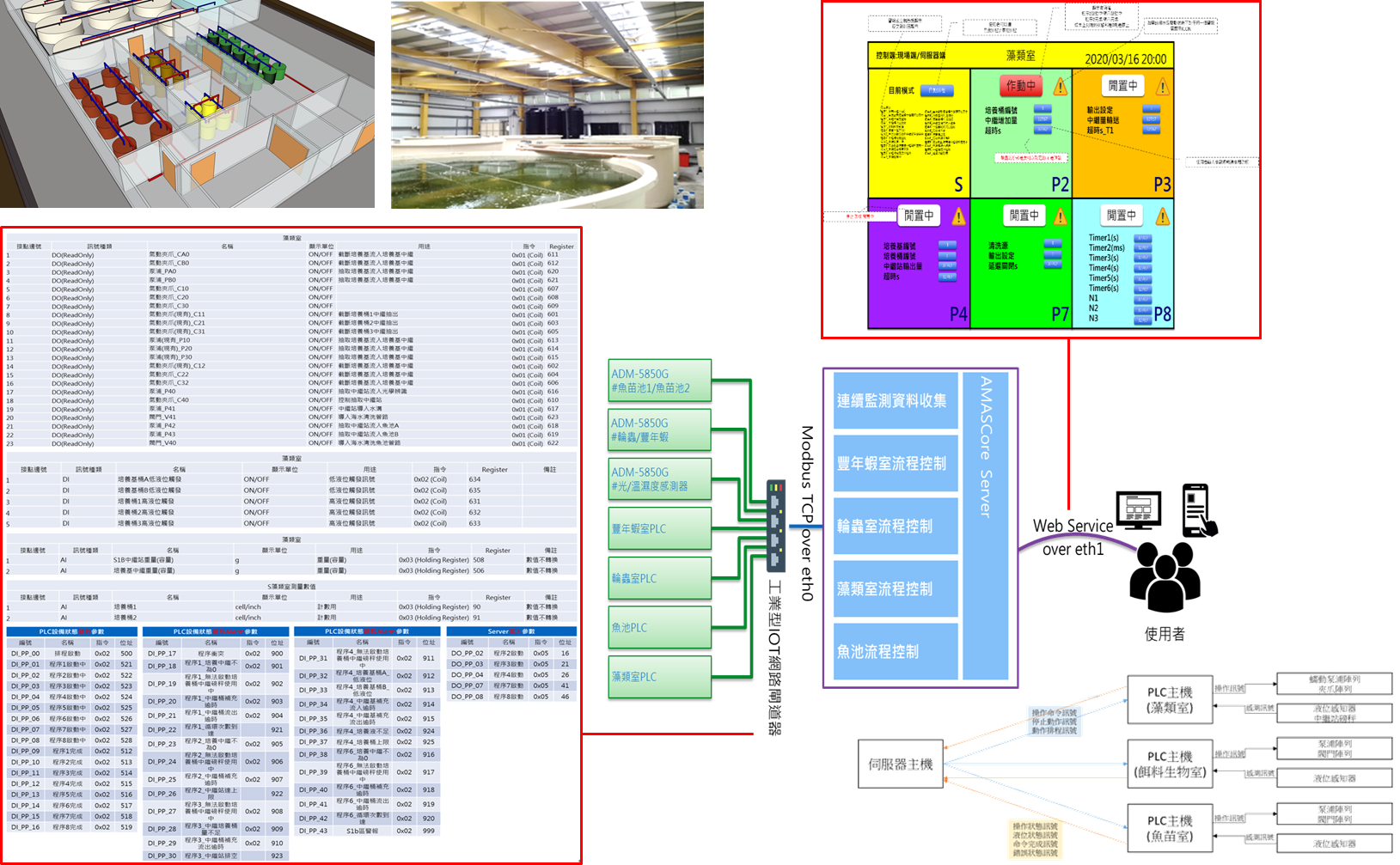

Fig. 2 System operation of breeding intelligent production system

Fig. 3 Schematic diagram of the operation of the central control platform |

|||||||

| ______________________________________________________________________________________________ | |||||||

|

|||||||

subscribe E-news

Vol.34 NO.1(2022.2)-3 Author information

|

Author

Chen Tzong-yueh |

|

|

|

Research members Chen Tzong-yueh1,Sheng-Chih Shen2,Yi-Min Chen1,Cheng-Yuan Kuo2 1Laboratory of Molecular Genetics, Department of Biotechnology and Bioindustry Sciences, College of Bioscience and Biotechnology, National Cheng Kung University, Tainan, Taiwan 2 Department of Systems and Naval Mechatronic Engineering, National Cheng Kung University, Tainan, Taiwan.

|

|

Key words Rotifer, Automated system, Programmable logic controller |

|

Research areas Translational research in biomedicine |

|

References [FAO] Food and Agriculture Organization of the United Nations, 2016, FAOSTAT Database, FAO. (1 December 2016; www.fao.org/faostat) Fisheries Agency (FA), “Taiwan Area Fisheries Yearbook 2020.” Fisheries Agency, Council of Agriculture, Executive Yuan, 2021. |

| Download |