|

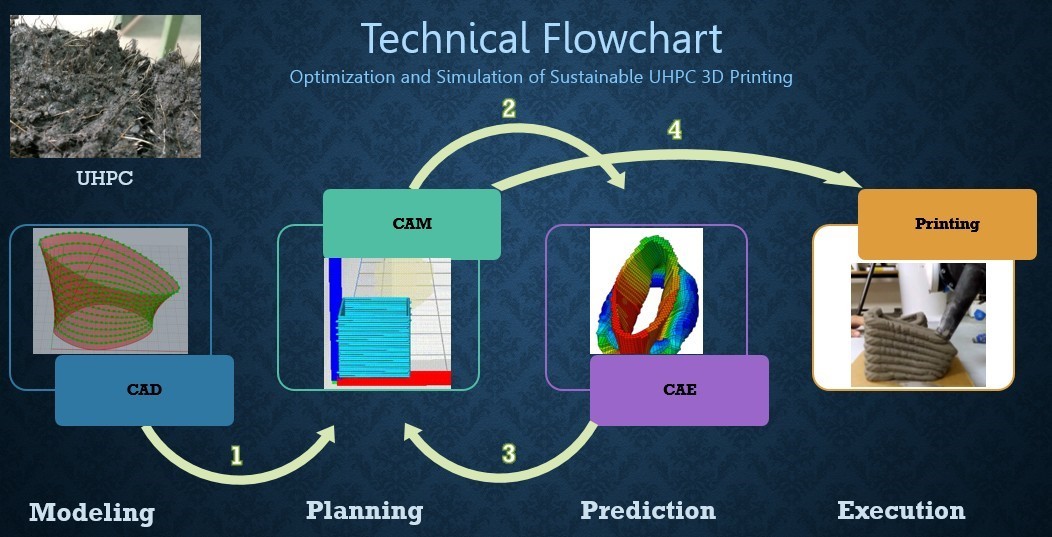

Optimization and Simulation of Sustainable Ultra-High Performance Concrete 3D Printing |

|||||||

| _________________________________________________________________________________________________________ | |||||||

|

In recent years, 3D printing technology has been noticed by the construction industry. However, there are many difficulties in applying it to reinforced concrete buildings. Concrete is not a traditional 3D printing material. There are still many needs for "extrusion" and "build". overcome. In addition, the prediction of the printing process and results, such as the analysis of materials, parameters, paths, structure, and stress, is not yet mature. And when the structure of the model is very complex, its data volume is very large, which is a very big challenge. Therefore, the team developed a printable concrete material and concrete 3D printing simulation technology. The team uses a new type of composite cement material-"Ultra-High-Performance Concrete" and adds a variety of fibers to the ultra high-performance concrete to minimize the shortcomings of traditional concrete (low tensile strength, easy cracking, and brittleness). Compared with ordinary concrete, It has extremely high toughness, as shown in Figure 1. In addition, its dense particle structure also has excellent durability against acid and alkali corrosion, so excellent mechanical properties and durability are major features of this new material. In addition, the team developed concrete 3D printing process simulation and optimization technology. First, according to the geometric shape of the object, the printing path, and nozzle angle were calculated. Figure 2 is a schematic diagram of the printing results of different nozzle angles. The above figure shows the fixed printing method. Highly sliced layer method; the picture below shows the nozzle changes with the angle of the profile. The obvious advantage of this strategy is to keep the contact surface between the two layers constant, thereby avoiding the geometric gap between the two layers. This structure is less It is easy to collapse and can reach a higher build-up height. Then perform the simulation analysis of the concrete 3D printing process, using the self-developed infinite element method to simulate, with time-varying material properties elements, analyze the stress distribution and deformation of the object during the manufacturing process, and then optimize the process parameters based on the analysis results, such as Displacement rate, extrusion rate, etc |

|||||||

|

Figure 1 Ductile behavior of ultra-high performance concrete

Figure 2 Ultra-high performance concrete 3D printing tangential printing method |

|||||||

| ______________________________________________________________________________________________ | |||||||

|

|||||||